Replacing COAX Hose on Eco-505 Injection System

The following are step by step instructions for installing our coax hose on a reel and at the spray gun. Please contact us if you have any questions with the procedure.

Installation of Coax at Hose Reel:

Install 1/2" x 1/2" hose barb on left feed of reel and 1/2" pipe thread x 3/16" tubing fitting on right feed. Use pipe sealant when installing fittings.

Place 1/2" clamp over hose to be tightened later. Feed 3/16" tubing through transition fitting and through 3/16" tubing fitting. To make this easier, put a small bend in the end of the tubing to allow it to follow curvature of fitting. (This will be cut off later). Be careful not to kink the 3/16" tubing while feeding through the transition piece.

Slide the 1/2" hose over barb fitting and clamp in place.

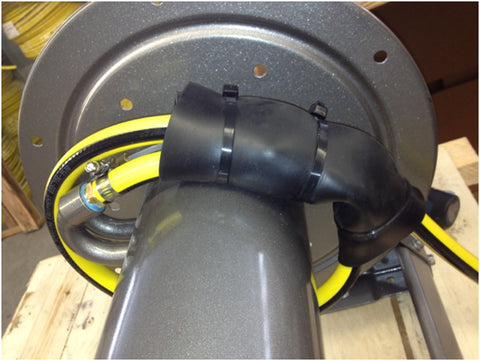

Connect the 1/2" hose to reel with 1/2" hose transition piece and clamp in place. Position clamps at a 45 degree angle to allow hose to rest on clamps to not damage the hose.

Connect 3/16" tubing to reel. To do this gently push tubing back into hose until you feel resistance. Cut tubing at length shown in picture using hose or tubing cutter. Do not use side cutters as this may result in crimping the end of the tubing and restricting flow. Slide ferrules as show in the picture below. An easy way to remember is fat end of ferrule to fitting.

Gently pull tubing out of hose to allow it to connect to reel. Tighten ferrule and nut at reel first and then transition fitting. Do not over tighten tubing fittings. This may result in the tube being crimped and reduction of flow.

Apply first wrap of hose over transition piece. There should be no kinks or folds in either line. Install rubber pad under transition piece and wrap. Fasten in place using tie straps. This process protects the hose from getting damaged by the brass fittings and also prevents the last wrap of hose being pulled off the reel.

Installation of Coax Hose to Spray Gun:

Remove screws for the top cover and loosen nozzle to allow access tot he top valve assembly.

Remove barb fitting from the back of the gun and remove the nut/ferrule on fitting on top of gun. Install hose clamp over hose to be tightened later. Install pipe sealant on barb fitting threads. Slide 3/16" tubing through barb fitting, into the back of the gun and out the top fitting.

Thread in hose barb fitting to back of gun. Slide 1/2" hose over barb and tighten clamp.

Gently slide tubing back into hose until you feel resistance. Trim tubing to length in picture. Install both sets of ferrules and nuts over tubing. Insure ferrules are installed correctly. (fat side towards fitting) View image in "installation at reel" instructions.

Slide tubing into gun and insure it is seated in gun properly. Tighten nut on upper valve first (closest to nozzle) and then tighten fitting at gun. Do not over tighten tubing fittings. This may result in line being crimped and reduction in flow.

Orient gun cover over top of gun and install screws to hold in place. Re-tighten nozzle.